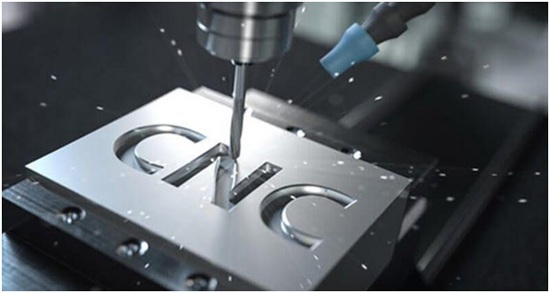

In the manufacturing world, there are several different methods for creating products. These methods can be broadly grouped into two categories: manual and automated. Within the automated manufacturing category, a wide range of different technologies and methods can be employed. One of the most popular and widely used automated technology types is CNC or computer numerical control. In this blog post, we will explain in depth what CNC machines are, how they work, and some of the most popular types.

What is a CNC Machine?

A CNC machine is any machine that is controlled by a computer. In most cases, these machines are used for fabrication or machining applications. There are many different types of CNC machines, but they all share one common trait: they use computer-controlled motors to move their cutting or shaping tools in specific ways in order to create the desired product.

The advent of CNC machines has revolutionized the manufacturing industry. These machines are faster and more precise than their manual counterparts, and they can be programmed to create products with a high degree of complexity. In addition, CNC machines can be operated with minimal supervision, which has led to increased productivity in factories around the world.

Types of CNC Machines

There are many different types of CNC machines available on the market today. Some of the most popular include:

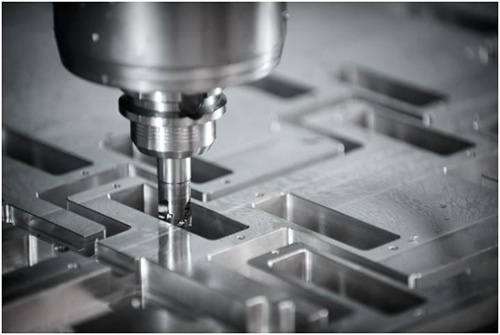

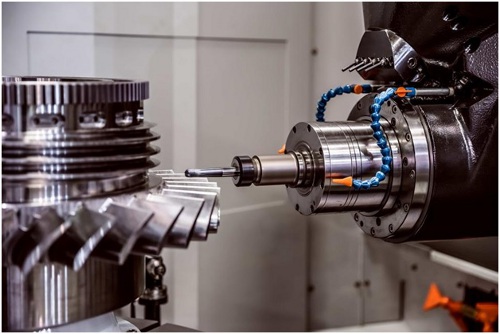

Milling Machines:

Milling machines are some of the most versatile CNC machines on the market. They can be used for a variety of tasks, including milling (of course), drilling, tapping, boring, and reaming. Milling machines usually have at least three axes (X, Y, and Z), but some models have as many as five or six axes. This allows them to create complex shapes and parts with relative ease.

Turning Centres:

Turning centres are another type of versatile CNC machine. They can be used for many of the same tasks as milling machines (drilling, boring, reaming, etc.), but they excel at one thing in particular: turning cylindrical objects (hence the name). Turning centres typically have at least two axes (X and Z), but some models have four or more (Y and/or B being the most common additional axes).

EDM Machines:

EDM stands for electrical discharge machining—a process that uses electrical sparks to remove metal from a workpiece. EDMs can be used to create very precise shapes and cuts that would be difficult or impossible to create using other methods. EDM machines usually have three or more axes (X, Y, Z & W being the most common), but some models have up to seven axes.

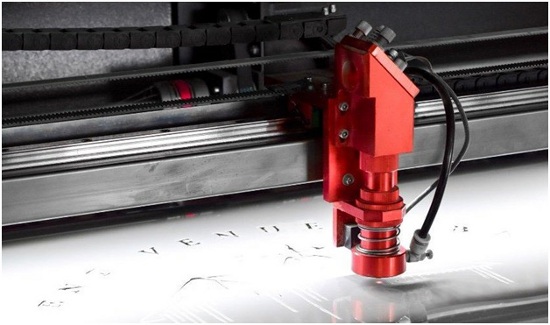

Laser Cutters:

Laser cutters use high-powered lasers to cut through metal (and other materials) with incredible accuracy and speed. Laser cutting usually have three or more axes (X, Y & Z), but some models have up to six axes (A & B being the most common additional axes).

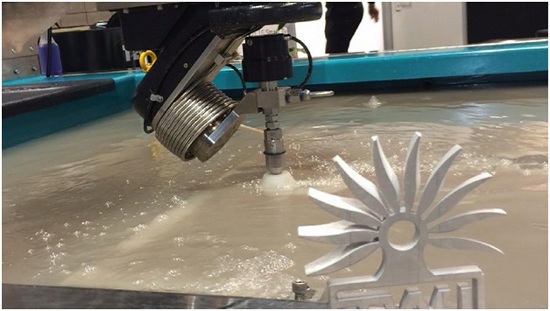

Waterjet Cutters:

Waterjet cutters use pressurized streams of water to cut through metal (and other materials) with incredible accuracy and speed. Waterjet cutters usually have three or more axes (X, Y & Z), but some models have up to five axes (A & B being the most common additional axes).

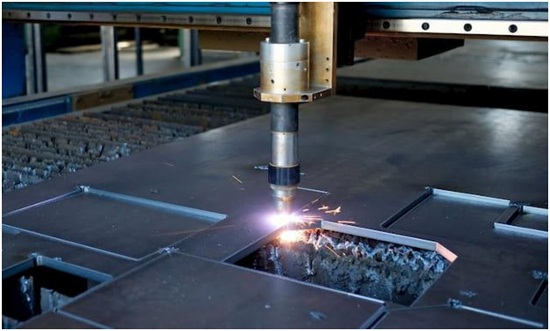

Plasma Cutters:

Plasma cutters use pressurized streams of plasma—ionized gas that is heated to an extremely high temperature—to cut through metal with incredible accuracy and speed. Plasma cutters usually have three or more axes (X, Y & Z), but some models have up to five axes (A & B being the most common additional axes).

Router Tables:

Router tables are specially designed tables that hold router bits. Routers are powerful tools that can be used for a variety of tasks, such as trimming, chamfering, rebating, and shaping. Router tables usually only have two axes (X & Y), but some models may also have a Z axis.

Specifications According to Needs

Each type of machine is designed for a specific purpose. Lathes, for example, are used to create cylindrical objects out of a variety of materials. Milling machines, on the other hand, can be used to create both flat and three-dimensional objects from various materials. Plasma cutters are typically used for cutting metal objects, while laser cutters and router tables are more often used for cutting wood or plastic objects. Waterjet cutters are generally used for cutting hard materials such as stone or ceramic tiles. No matter your specific needs, there is almost certainly a type of CNC machine that can meet them.

Conclusion

Suppose you are considering adding CNC machining technology to your factory or business. In that case, this overview should give you a better understanding of what options are available to you and how these machines can benefit your operations. As you can see, there is a wide range of different types of CNC machines available on the market today—each with its own strengths and weaknesses—so it is important that you do your research before making a purchase decision. With so many different options available, finding the right CNC machine for your needs shouldn’t be too difficult—but if you need any help along the way, don’t hesitate to reach out to an experienced CNC machinery and services provider.

Thanks for reading!